How to ? thermoform complex canopies

by Renaud POUGE

Shown in Wingmaster n°25  (november-décember

2001 - french aircraft modeler magazine), the

basic

onmoulding technic had already helped me many times to

have crystal clear canopies. But

here comes another problem

when you have to deal with canopies with varying shapes, that goes up

and down, like the blister of a

Mosquito PR

XVI or like a Malcom Hood canopy of a P-47

Razorback. You

can't just apply the rhodoïd on the master...without induction, you

will obtain a result as the red line on this pictures on the right.

(november-décember

2001 - french aircraft modeler magazine), the

basic

onmoulding technic had already helped me many times to

have crystal clear canopies. But

here comes another problem

when you have to deal with canopies with varying shapes, that goes up

and down, like the blister of a

Mosquito PR

XVI or like a Malcom Hood canopy of a P-47

Razorback. You

can't just apply the rhodoïd on the master...without induction, you

will obtain a result as the red line on this pictures on the right.

So,

i decided to create a thermoforming machine.

So,

i decided to create a thermoforming machine.

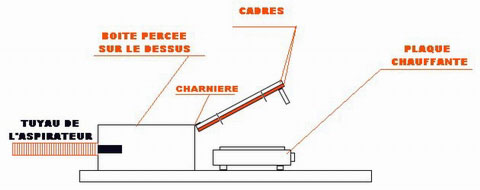

For this, 4 elements are required

:

- 1 regular heating source

- 1 frame to support the transparent plastic sheet

- 1 box, pierced on its to, to obtain an uniform induction

- & 1 vacuum cleaner (+ flowers for your wife if she is recalcitrant).

Heating is insured by a hotplate (between 14€ to 16€ in supermarkets). Just behind that, i've put a box which upper side is shaped to receive A-4 sized sheet (you can do it smaller). The side opposite to the plate is pierced to plug the vacuum cleaner pipe. On the upper side, it is pierced by many holes to distribute the induction.

i then realised 2 identical frames between which will be inserted the celluloïd sheets. The inner frame is fixed to the box by an hinge, in order to put the celluloïd sheet on the hotplate when you rotate it. Butturflies srews maintain the 2 frames, trapping the plastic sheet.

Positioned on top of the hotplate, the sheet will soften. As soon as it seem soften enough, you just have to turn the hoover on & rotate the frames on the master. And 'voilà' heating & induction will do the rest for you.

|

|

|

|

In this issue:

Intro Modern : X-32

versus X-35, tomorrow U.S.Air Force hot bee / WWII : The

1:72 Junker Ju-388 for advanced modelers only...

Technic : How to ? Thermoform complex canopies - Painting : Do

it yourself : stencil markings.

© Club du Theil |2001-2004 | Contact :club-du-theil@tiscali.fr